The 25-Second Trick For Wood Flooring

Wiki Article

The Definitive Guide to Hardwood Floor Installation

Table of ContentsFascination About Hardwood FlooringGetting My Laminate Flooring To WorkGet This Report on FlooringThe smart Trick of Flooring Stores That Nobody is DiscussingNot known Facts About Hardwood Floor InstallationSome Known Factual Statements About Flooring Stores The 9-Minute Rule for Flooring Stores

Before applying the second layer, examine the flooring for any kind of problems. If there holes or fractures, use the epoxy filler and wait for 12 16 hours for it to dry.Our epoxy floor installers will certainly likewise do justice to the product with expert setup solutions.

Close this dialog window Share & Even more Back to story Remark on this job this web link is to an exterior website that may or may not meet access guidelines.

All about Hardwood Floor Installation

The procedure of measuring, pigmenting, blending, double potting, putting and also spreading out is duplicated till the floor is finished. Glass, Cast 3 epoxy covering material has excellent self-levelling homes, so will only need easy work to ensure that it has complete protection and a constant density - then the material will do the remainder of the work.Glasscast 3 is likewise self-degassing so the bubbles will pop by themselves, although we saw a tiny patch of flooring where bubbles really did not seem to be popping - this might be because of a small patch of flooring not being pre-sealed - to overcome this we swiftly passed over the surface with a lp torch to burst them.

As soon as you're happy with the flooring it's time to seal the space and leave it to completely treat - this will certainly enable the resin to degas, self-level as well as cure to an outstanding high gloss coating such as this! Remember it is very essential to seal the space to guarantee that there are no draughts as this might trigger dust and also particles to land in the resin throughout the cure.

What Does Wood Flooring Do?

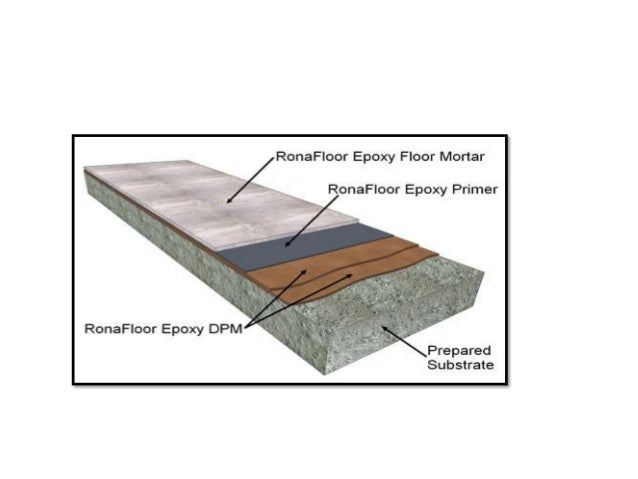

The listed below guide is a summary of the actions on how to use epoxy flooring paint. This guide relates to a simple roller used floor. Such epoxy systems are generally used with one layer of guide & 2 coats of epoxy floor covering. These floors are appropriate for light and also tool wear as well as tear, best for garages as well as storeroom.A Self leveling epoxy floor tends to have a. Preparing the surface prior to applying the epoxy Preparation of the substratum is required in order to make sure attachment in between the epoxy item as well as the substrate.

Indicators on Flooring Installation You Should Know

Utilizing a floor grinder allows you to utilize different types of grinding tools depending on your requirements. For instance if you require to grind rough concrete, you need to use a hostile as well as crude ruby device. If you require to give the existing surface area a light sanding, you can select instead to utilize a high grit fining sand device.This is why we apply epoxy guide. Always prime the flooring, do not think insurance claims that priming is not required. Priming will provide your flooring a longer life and much better bond to the substratum. In addition it will certainly seal the substrate and reduce the danger of bubbles and also gasses in your last epoxy layer.

Make sure that the areas are aerated correctly. In many cases, you will use the guide and notification that the product gets really swiftly absorbed by the substrate. This is very typical with dusty and also soft concrete based floorings. on top of the initial one. Utilize a proper electrical mixer to mix the An and B element of the primer.

Examine This Report about Laminate Flooring

Most possibly it will additionally require a little bit of sanding prior to continuing to the following step. Several days have actually probably passed because you started the process of mounting your epoxy floor. If you have done all the previous steps correctly, you are ultimately ready to apply the initial layer.

You will need to gently sand these locations to eliminate any type of marks that might be noticeable on the last flooring. Make use of a vacuum cleaner to gather any dirt.

Hardwood Flooring Cost - An Overview

See to it that all the brand-new fractures as well as holes are secured & filled up prior to starting the next layer. If required wait an added dry for the cement to completely dry before re-coating. If you followed the epoxy floor covering process in this article, then the last coat should be the simplest action.

This training course was established for applicators that want to get into epoxy flooring. You will certainly obtain that has actually been distilled into over 20 lessons - hardwood floor installation.

Vinyl Flooring Things To Know Before You Buy

Action 2: Examine Climate Projection Prior to you begin see to it the air temperature is 60 levels and also rising which your slab goes to a minimum of 50 degrees. It will be near difficult for the epoxy to establish if you try to do this in the wintertime. Action 3: Sweep It Completely Utilize a mop to cleanse the piece.The goal is to not over-wet the floor so it will also dry promptly. The citric acid will certainly help open up the top pores of the concrete so the epoxy adheres well.

Step 8: Test For Existing Sealer Check to see cheap hardwood flooring if there is still top sealant on the floor. If the water grains up, there is an existing sealant that might interfere with carpet stores the bond of the epoxy.

Report this wiki page